What colour floor pad should you be using?

Although experienced floor maintenance professionals will have a thorough knowledge of what pads to use for which processes and conditions, for operatives approaching a job with less knowledge or training there can be a confusing range of options.

By and large, the industry standard colour-coding system works from light to dark, with white the finest, working up through tan, red, green and blue to brown and black, with the coarsest fibres.

However, there’s more to a buffing pad than just its coarseness, so here’s more detail on the different colours and how they should be used. Please note, there may also be differences between the same colour pad from different manufacturers.

Stripping pads - Black and Brown

Black and Brown are highly abrasive, aggressively removing floor polishes and finishes to prepare for re-finishing. The coarsest type of pads available, with heavy fibres, and an open weave to prevent clogging or loading, They are ideal for removing layers of floor polish. They will also remove heavy soiling such as concrete splashes, but may still be unable to remove certain adhesives such as mastic.

There are no formal manufacturer standards between which colours of stripping pads are which grade, but black and brown are the predominant colours for the toughest pads. They are often used ‘wet’ ie a stripping solution is applied to the floor, either via the floor machine or by mop, and left to act for a few minutes before being scrubbed.

These should be used with a low-speed machine (150-200 rpm) as high-speed machines are not suitable for stripping polish. The soiled solution needs to be picked up by a mop or wet-vacuum cleaner and rinsed.

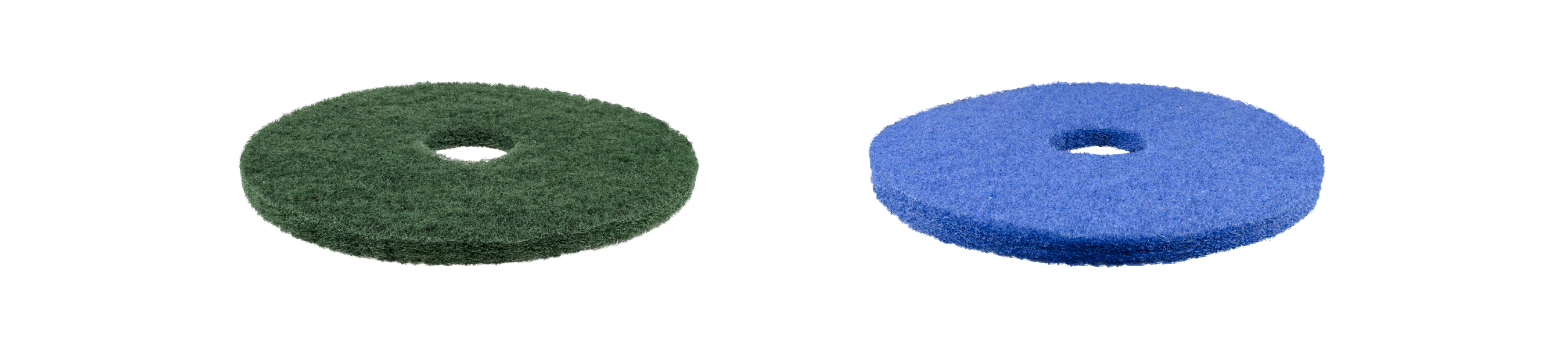

Scrubbing pads - Green and Blue

Green and blue scrubbing pads are not as heavy as black or brown pads, but will still remove heavy soils and marks. However, they are also likely to take a thin top layer off emulsion polishes, leaving a dull surface perfect for recoating and burnishing.

Both may be used wet, the blue pad is also good for ‘spray cleaning’ which is an excellent maintenance technique and uses much less water than wet scrubbing. Both scrubbing and spray cleaning will remove medium levels of soil but will not remove all the polish.

These pads are both suitable for high-speed applications (300-500 rpm) but not ultra-high-speed use. They should not be used for burnishing as they are too abrasive and will spoil and remove the surface of the polish.

Spray cleaning pads - Red and Tan

The Red lightweight scrubbing pad is the most commonly used for regular cleaning and maintenance. It is suitable for dealing with light soil and restores a soft shine to the surface of a polished floor.

Tan pads are finer and can be used with high-speed machines (300-500 rpm). They are commonly used for spray cleaning – the floor is pre-sprayed with a cleaning agent or floor maintainer before buffing with a red or tan pad.

Burnishing pads - White and Pale blue

Burnishing pads are used for achieving the finish to a polished floor, leaving a high shine and helping the polish to set by warming the surface through their friction. They are used at high speed and are gentle enough to use on waxed floors.

White is the softest pad, which means it leaves the brightest shine on the floor but also is less durable. White pads can be used up to medium-high speed (350 rpm) as they are liable to overheat at higher speeds.

A relatively new development is the pale blue thermal pad, which can be used at ultra-high speeds (1500-2000 rpm) to achieve an exceptionally shiny finish. These pads have a much more aerated weave to allow more air to reach the floor and stop the surface from overheating. Some manufacturers use other colours for ultra-high-speed pads.

Melamine Pads

Although not technically a buffing pad, melamine floor pads are gaining massively in popularity among floor maintenance teams, as users discover how effective they can be on natural stone, terrazzo, wooden or tiled floors.

Made from the same material as the magic sponge, they are more expensive than standard floor pads but can remove stains and scuff marks and restore a new appearance to the floor in a way that other pads can’t, using only water. They should be used at low speed (150rpm) to avoid wearing through the pad too fast.